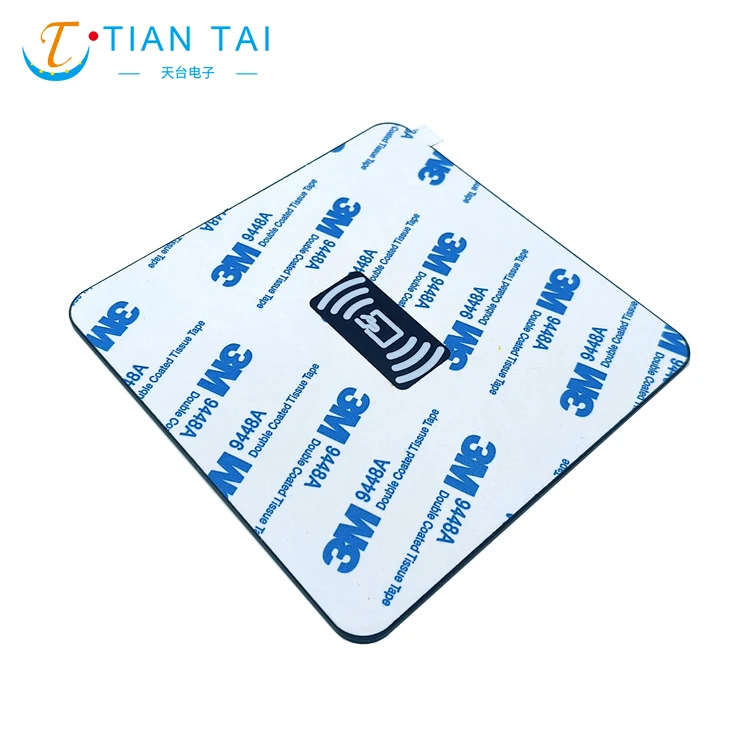

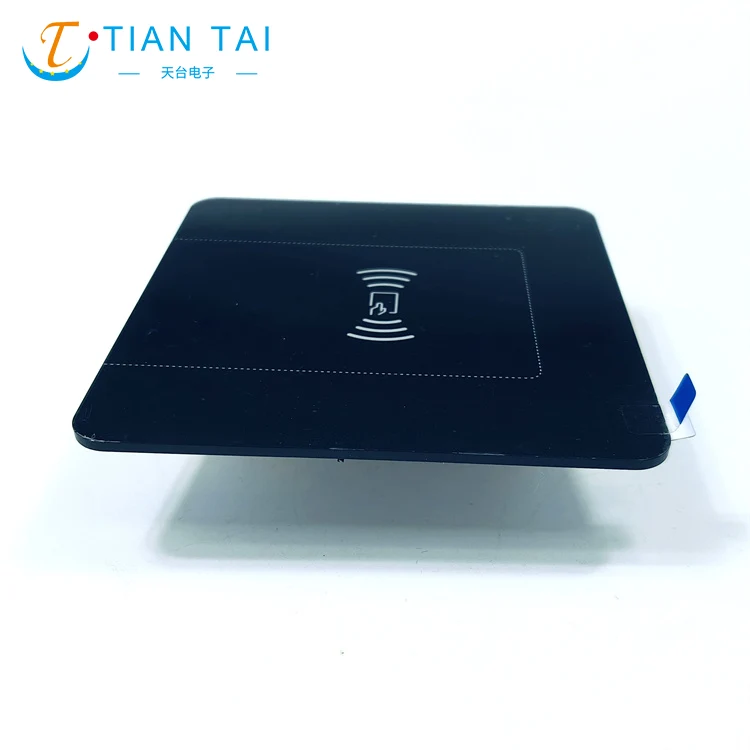

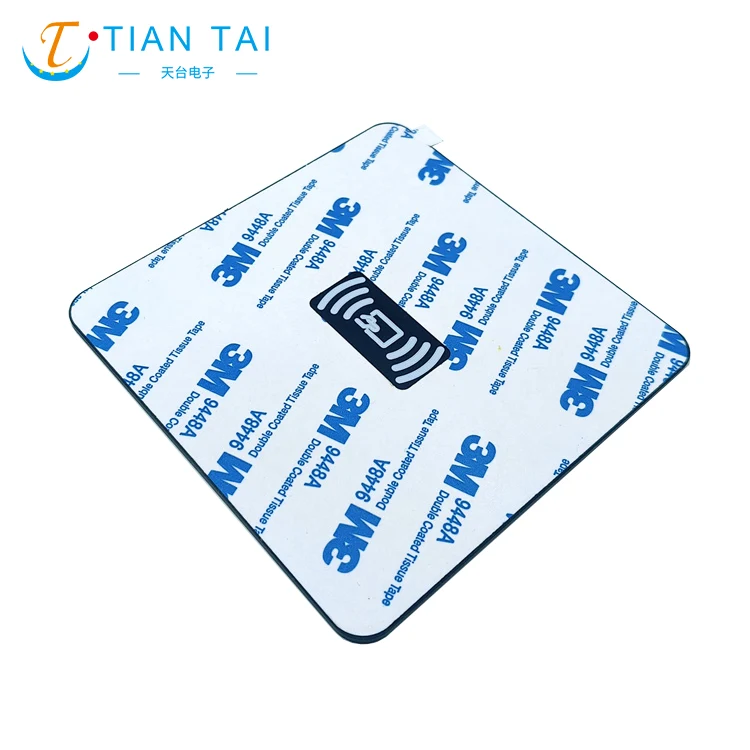

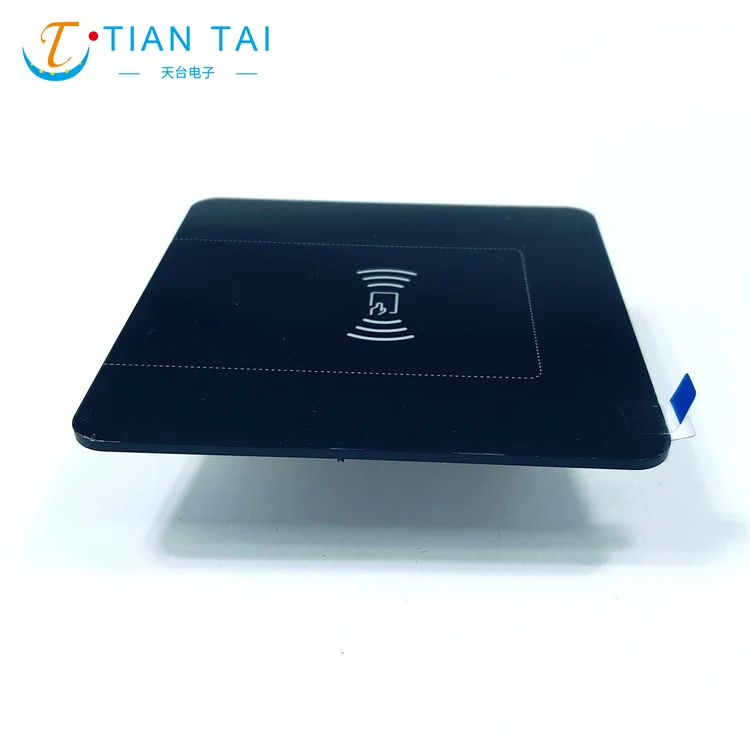

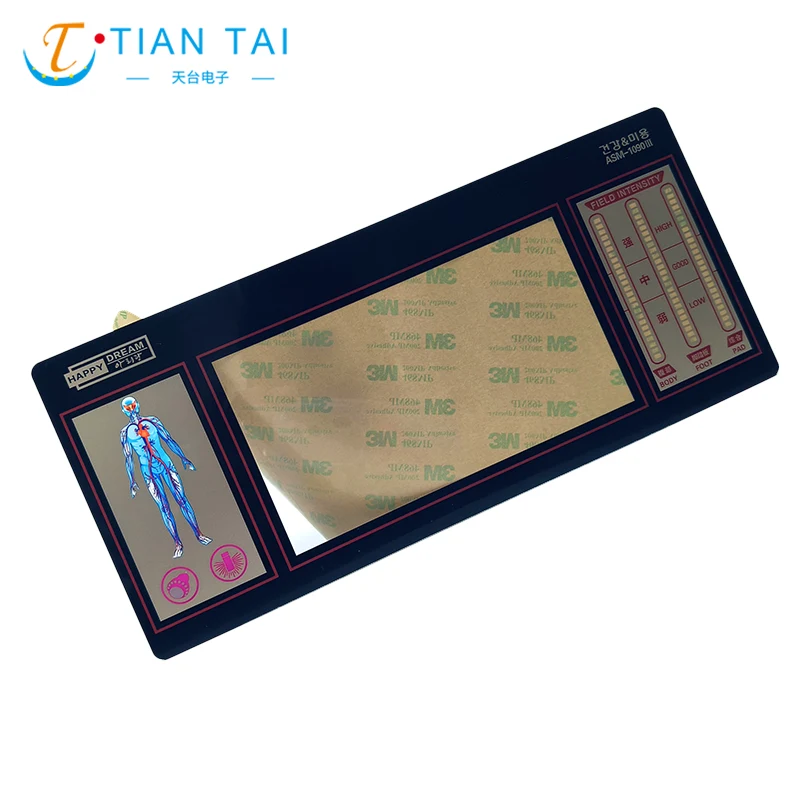

Arcylic Graphic Overlay

Send Inquiry

Our design engineers can employ a variety of finishing methods and materials for touchscreen interfaces, control panels, UV resistance, anti-glare, and other application requirements. For a wide range of industries, including appliances, medical equipment, consumer electronics, etc., we have produced graphic overlays and decals. At Dongguan Tiantai, we can design overlays that can be used as membrane switch assemblies or as standalone labels.

Used Graphic Overlay Materials:

Graphic overlays can be made from a range of materials to match various products and environments. Several of the most frequently made use of are:

Polyester : Polyester graphic overlays are very durable. They can show no indicators of wear even after 1,000,000 actuations. Additionally, they withstand direct exposure to chemicals and various other extreme environmental substances and conditions.

Polycarbonate : Polycarbonate graphic overlays are cheaper. Additionally, they provide exceptional optical clarity and quality. Nevertheless, they reveal indications of wear after 100,000 actuations and need tough coverings if there is a danger of them being revealed to chemicals.

Acrylic : Acrylic graphic overlays are lighter than glass. Additionally, they are solid and inflexible, that makes them very durable. They are best matched for applications involving the transmission and diffusion of light.

Glass: Glass graphic is a common screen covering material for electronic devices, usually made of tempered glass, which has the characteristics of high hardness, wear resistance and good light transmittance.